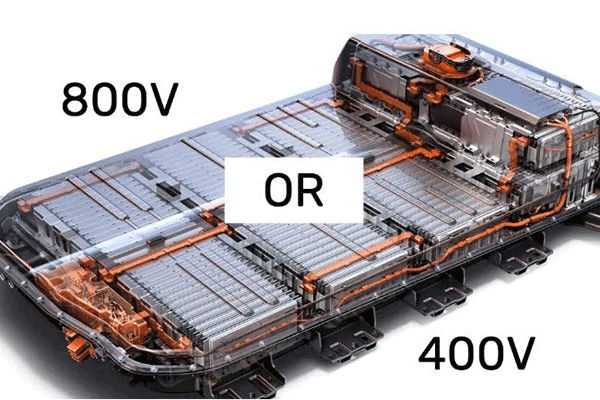

As the global demand for sustainable transportation solutions continues to rise, advancements in electric vehicle technology have come into focus. Among these, the voltage architecture of electric vehicles plays a crucial role in improving charging speed and efficiency. This article will explore the differences between 400V and 800V voltage architectures.

Why High-Voltage Electric Vehicles are Needed

In traditional gasoline vehicles, refueling at a gas station requires only a few minutes, starkly contrasting with the speed at which EVs charge. Just a few years ago, charging an EV took several hours, with some vehicles even exceeding 10 hours. However, advancements in voltage architecture have introduced fast charging, reducing charge times to under half an hour. EV manufacturers have keenly recognized this issue, understanding that faster charging speeds can alleviate some of the range anxiety among users. This realization has spurred a collective effort to accelerate the process and shorten charging durations.

There are two primary approaches to accelerate charging speeds. One involves the development of new battery technologies, such as solid-state and graphene batteries, the latter being up to 60 times faster than the lithium-ion batteries commonly used in modern EVs. The other solution is to upgrade the electrical architecture of electric vehicles, for instance, shifting from a 400V to an 800V system. Voltage, also known as electric potential difference or electromotive force, measures the energy difference per unit charge created by a difference in electric potential within a static electric field. Simply put, similar to how water pressure is determined by the height of the water level, a higher voltage means faster charging.

Differences in Voltage Architectures

Charging Capability Comparison

The upper limit of EV charger speeds is generally denoted in amperes, for example, a charger’s power output is 125 kW, but the connector is rated for 200A. Let’s compare the charging processes of two types of electric vehicles: one with a 400V architecture and the other with an 800V architecture.

Using our knowledge of physics, power (W) = voltage (V) x current (A). Without considering the charging speed curve, when charging an 800V vehicle, 125kW/800V equals 156.25 A. Since the cable’s rated current is below 200A, the vehicle can fully utilize the 125kW charging power.

However, when charging a 400V vehicle, 125kW/400V equals 312.5 A, exceeding the cable’s rated value of 200A. At this point, the power transfer is 400V x 200A, which is only 80kW. This means it cannot fully utilize the 125kW charging station, resulting in a significant difference in charging speed.

Advantages of the 800V Architecture

The design cost of the 800V architecture is higher, yet this has not deterred major brands from competing and continually increasing voltage levels. By 2025, it is anticipated that 800V will become the standard for electric vehicles, significantly reducing the time it takes to charge an EV.

Furthermore, a higher voltage results in lower current, thereby producing less heat. This is beneficial for the batteries of electric vehicles, as it reduces the burden on the battery cooling system, minimizes the risk of thermal runaway, and allows charging cables to be thinner and lighter, making them easier to handle. The 800V system also means that the internal cables and electrical components of the electric vehicle can be thinner and smaller, thus reducing the overall weight of the vehicle. For heavy electric vehicles, weight reduction is crucial.

Supporting Systems for 800V Voltage

As the voltage of electric vehicles increases, charging facilities need to be improved accordingly. For instance, supercharging stations with a capacity of 350kW are becoming more widespread, aligning with the charging logic of 800V vehicles. Generally, charging stations with a power output of over 300kW are fully utilized by vehicles with an 800V architecture, enhancing the charging speed.